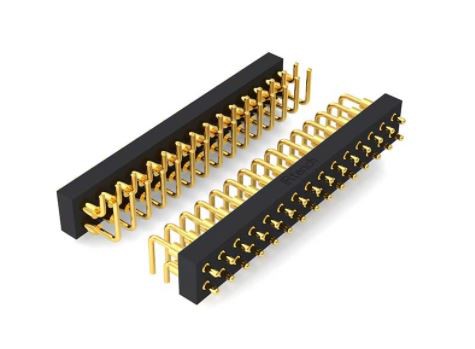

Zoo heev electroplating technology Pogo Pin Rhodium-plated

Muaj ntau cov txheej txheem electroplating thiab cov khoom siv. Kub plating yog peb cov txheej txheem ntau tshaj plaws thiab cov khoom siv, tab sis palladium plating, rhodium plating, thiab ruthenium plating yog zoo dua li kub plating.

Kub-plating Kub-plating siv cov kub tiag tiag, txawm tias nws tsuas yog plated nrog ib txheej nyias, nws twb tso nyiaj rau ze li ntawm 10% ntawm tus nqi ntawm tag nrho cov khoom siv hluav taws xob. Kub plating siv kub raws li txheej txheej plating, ib qho yog los pab kev vuam, thiab lwm yam yog tiv thaiv corrosion; txawm tus ntiv tes kub ntawm lub cim xeeb sticks uas tau siv ntau xyoo los tseem ci ntsa iab.

Qhov zoo: muaj zog conductivity, zoo oxidation kuj, lub neej ntev; ntom plating, kuj hnav-tiv taus, feem ntau siv hauv vuam thiab ntsaws lub sijhawm. Disadvantages: tus nqi siab dua thiab tsis zoo vuam lub zog.

2. Tshuaj kub/immersion kub Chemical nickel immersion kub (ENIG), los yog tshuaj nickel kub, immersion nickel kub, abbreviated rau tshuaj kub thiab immersion kub. Immersion kub yog ib txoj kev tshuaj, ib txheej tuab ntawm npib tsib xee-kub alloy nrog cov khoom siv hluav taws xob zoo yog qhwv rau ntawm qhov chaw tooj liab thiab tuaj yeem tiv thaiv PCB rau lub sijhawm ntev. Lub deposition thickness ntawm lub puab txheej ntawm npib tsib xee feem ntau yog 120 ~ 240μin (kwv yees 3 ~ 6μm), thiab deposition thickness ntawm txheej txheej kub yog feem ntau 2 ~ 4μinch (0.05 ~ 0.1μm). Immersion kub tuaj yeem ua rau PCB kom ua tiav cov khoom siv hluav taws xob zoo thaum siv mus ntev, thiab nws kuj muaj kev tiv thaiv ib puag ncig dua li lwm cov txheej txheem kho saum npoo tsis muaj.

Qhov zoo:

ib. Qhov saum npoo ntawm PCB kho nrog kub yog tiaj tus heev thiab muaj kev sib raug zoo, uas yog tsim rau kev sib cuag ntawm lub pob.

b. Immersion kub muaj zoo heev solderability, thiab kub yuav sai sai yaj mus rau hauv lub molten solder los ua ib tug hlau compound. Qhov tsis zoo: Cov txheej txheem yog qhov nyuaj, thiab cov txheej txheem yuav tsum tau tswj nruj me ntsis kom ua tiav cov txiaj ntsig zoo. Qhov teeb meem tshaj plaws yog qhov PCB nto uas tau kho nrog kub yog ib qho yooj yim los tsim cov txiaj ntsig dub, uas cuam tshuam rau kev ntseeg tau.

3. Piv nrog npib tsib xee thiab kub, ENEPIG muaj ib txheej ntxiv ntawm palladium ntawm npib tsib xee thiab kub. Nyob rau hauv cov tshuaj tiv thaiv deposition ntawm hloov kub, lub electroless palladium txheej yuav tiv thaiv cov nickel txheej thiab tiv thaiv nws. Ntau dhau corrosion ntawm qhov hloov kub; palladium yog npaj txhij rau immersion kub thaum tiv thaiv corrosion los ntawm kev hloov cov tshuaj tiv thaiv. Lub deposition thickness ntawm ib tug npib tsib xee feem ntau yog 120 ~ 240μin (kwv yees 3 ~ 6μm), lub thickness ntawm palladium yog 4 ~ 20μin (li 0.1 ~ 0.5μm); Lub deposition thickness ntawm kub yog feem ntau 1 ~ 4μin (0.02 ~ 0.1μm). Qhov zoo: Nws muaj ntau yam kev siv. Nyob rau tib lub sijhawm, npib tsib xee-palladium-kub kuj tseem nyob rau hauv kub, uas tuaj yeem tiv thaiv cov teeb meem kev ntseeg tau zoo los ntawm cov teeb meem dub. Qhov tsis zoo: Txawm hais tias npib tsib xee palladium kub muaj ntau yam zoo, palladium yog kim thiab yog ib qho khoom siv tsawg. Nyob rau tib lub sijhawm, zoo li Immersion Kub, nws cov txheej txheem tswj cov cai nruj.

Cov khoom siv tshuaj lom neeg ntawm rhodium yog qhov ruaj khov, thiab nws nyuaj rau kev hnov mob nrog sulfide thiab carbon dioxide roj hauv huab cua. Nyob rau hauv chav tsev kub, nws yog insoluble nyob rau hauv nitric acid thiab nws cov ntsev, thiab txawm insoluble nyob rau hauv dej. Nws yog ruaj khov rau ntau yam muaj zog alkalis, tab sis rhodium yog soluble hauv concentrated sulfuric acid. Lub cev lub cev ntawm rhodium yog qhov zoo. Ntxiv nrog rau kev hnav zoo thiab hluav taws xob conductivity, nws muaj peev xwm rov qab xav txog, thiab nws cov coefficient ntawm kev xav tuaj yeem ncav cuag 80% (nyiaj yog 100%), thiab nws tuaj yeem nyob tsis hloov mus ntev. Yog li ntawd, nws yog feem ntau siv raws li ib tug anti-silver discoloration txheej. Tom qab kev sim, 0.1um rhodium txheej tuaj yeem tiv thaiv cov xim nyiaj los ntawm kev hloov xim rau ntau xyoo. Cov txheej txheem rhodium muaj kev tiv thaiv qis heev thiab siab hardness, yog li nws feem ntau siv los ua txheej rau cov ntsiab lus sib cuag.

Lub vuam kev ua tau zoo ntawm rhodium tsis zoo heev, vim hais tias cov kev ntxhov siab sab hauv ntawm txheej yog qhov loj. Rhodium plating thev naus laus zis tau pib siv hauv Tebchaws Meskas hauv xyoo 1930, tab sis nws yog siv rau cov hniav plating. Tom qab ntawd, nrog kev loj hlob sai ntawm kev lag luam hluav taws xob, rhodium plating tau ua lub luag haujlwm tseem ceeb hauv kev tiv thaiv cov nyiaj tsis muaj xim thiab cov ntsiab lus hluav taws xob. Nyob rau hauv xyoo tas los no, rhodium plating tau dhau los ua neeg nyiam hauv cov hniav nyiaj hniav kub electroplating kev lag luam. Electroplating ib txheej ntawm rhodium rau saum npoo ntawm cov hniav nyiaj hniav kub tuaj yeem tiv thaiv cov nyiaj tsis zoo. Tus nqi yog pheej yig, thiab nws tuaj yeem qhia tau zoo li platinum zoo nkauj. Vim tias qhov ntom ntawm rhodium tsawg dua li ntawm platinum, tus nqi ntawm rhodium plating yog qis dua li ntawm platinum plating.