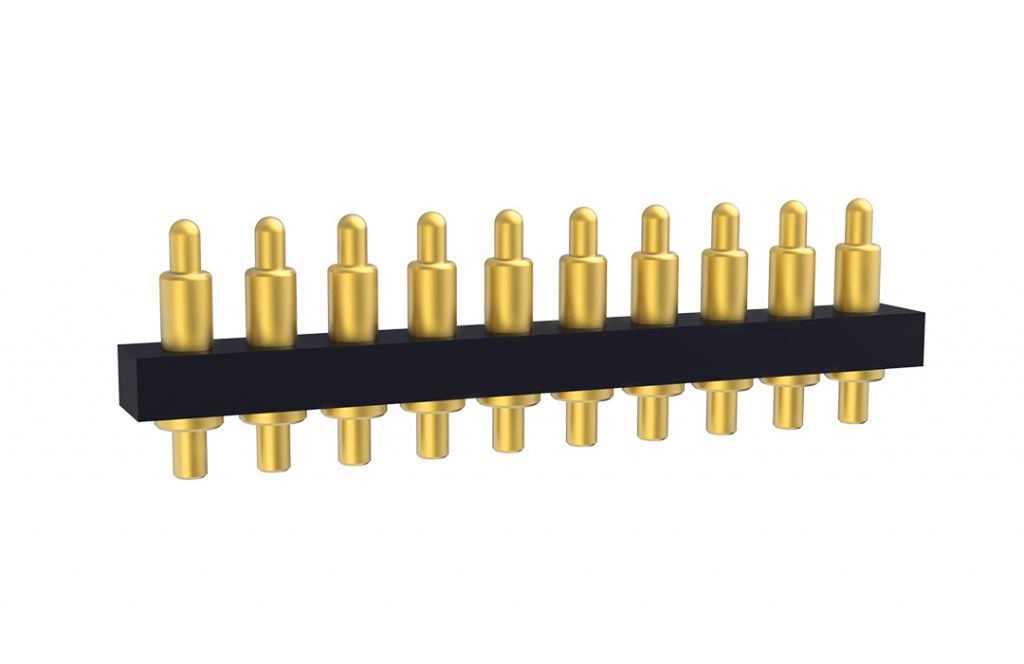

Dab tsi yog qhov txawv ntawm lub caij nplooj ntoos hlav pogo pin qauv?

Lub caij nplooj ntoos hlav thimble yog cov cuab yeej precision muaj peb ntu: rab koob, lub caij nplooj ntoos hlav, thiab rab koob. Cov kev cai hauv kev ua cov txheej txheem kuj tsim nyog thiab nruj.

Ua ntej, flat-head caij nplooj ntoos hlav thimble koob ncej:

1, lub caij nplooj ntoos hlav thimble koob ncej tiaj tus taub hau nta: txheej txheem tsim khoom yooj yim, tus nqi qis;

2. Kev ua thiab kev tsim khoom: txoj kev xa khoom → kev co sib tsoo txheej txheem (tshem tawm cov burrs, cov kaum sab xis) → electroplating txheej txheem;

3. Cov txheej txheem sib tsoo trembling yog tshem tawm cov burrs thiab cov kaum ntse ntse uas tshwm sim thaum ua haujlwm thiab txo qhov tshwm sim ntawm shakshuka thaum lub sijhawm zawm.

Thib ob, hypotenuse hom caij nplooj ntoos hlav thimble koob ncej:

1. Cov yam ntxwv ntawm lub hypotenuse ntawm rab koob ncej ntawm lub caij nplooj ntoos hlav thimble: tam sim no feem ntau siv nyob rau hauv lub Hoobkas, nrog zoo hluav taws xob yam ntxwv;

2, kev ua thiab kev tsim khoom: kev xa khoom → kev ua haujlwm thib ob ntawm bevel ntug → kev co sib tsoo txheej txheem (tshem tawm ntawm burrs, cov kaum sab xis) → electroplating txheej txheem;

3. Cov txheej txheem sib tsoo yog tshem tawm cov burrs thiab cov kaum ntse ntse uas tshwm sim thaum ua, thiab txo qhov tshwm sim ntawm shakshuka thaum zawm;

4. Muaj ob hom bevel kaum sab xis nyob rau hauv lub Hoobkas tam sim no: 1) 12 ° → Nws yog ib qho yooj yim rau kev sib sau ua ntej kev npaj ntawm rab koob, thiab qhov ntev ntawm lub rooj zaum koob yog luv, uas txuag tau qhov chaw. 2) 18 ° → Tam sim no feem ntau siv nyob rau hauv lub Hoobkas, qhov ntev ntawm lub koob txhaj tshuaj yog ntev, thiab nruj nreem nrog cov yeeb nkab phab ntsa tom qab sib dhos yog siab thiab tus nqi kuj zoo.

Thib peb, thim rov qab drilling hom caij nplooj ntoos hlav thimble koob ncej:

1, lub caij nplooj ntoos hlav thimble koob ncej thim rov qab drilling feature: haum rau cov khoom nrog loj contraction stroke;

2. Kev ua thiab kev tsim khoom: kev xa khoom → kev ua haujlwm thib ob rov qab drilling → chattering sib tsoo txheej txheem (tshem tawm burrs thiab cov kaum sab xis) → electroplating txheej txheem;

3. Cov txheej txheem sib tsoo yog tshem tawm cov burrs thiab cov kaum ntse ntse uas tshwm sim thaum ua, thiab txo qhov tshwm sim ntawm shakshuka thaum zawm;

4. Tam sim no muaj ob hom ntawm lub kaum sab xis ntawm rov qab drilling hauv lub Hoobkas: 1) 120 ° → yooj yim rau laum. 2) 160 ° → Nws tsis yooj yim rau kev xyaum, tab sis nws tuaj yeem ntxiv qhov chaw rau lub caij nplooj ntoo hlav.

caij nplooj ntoos hlav thimble connector belongs rau ib hom ntawm connector, nws muaj nuj nqi yog heev yooj yim mus ua si lub luag hauj lwm ntawm ib tug kev twb kev txuas. Lub caij nplooj ntoos hlav thimble connectors tuaj yeem tsim kho raws li cov kev xav tau ntawm kev ua haujlwm, thiab cov kev qhia tshwj xeeb sib txawv tuaj yeem xaiv hauv kev tsim qauv.